We only source Japanese paper from reputable importers. Prints on such paper are more saturated, have even colors, and the graphics appear clearer.

The inks we utilize are sourced from reputable Japanese companies. We can achieve high definition shapes, patterns, and graphics with the top-grade ink material.

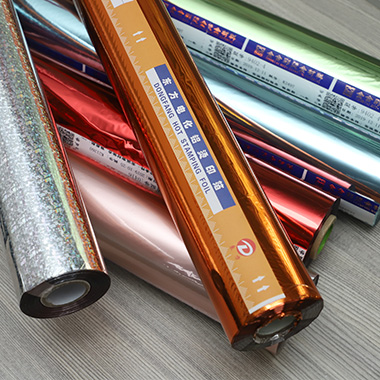

All foil material incorporated to our washi tapes is made in house, and have 100+ color options for your different needs (standard gold and silver foil/ hologram siver/ rose gold/ champagne gold, etc), guaranteeing the quality of foil and make it do not peef off.

Unlike the traditional printing machinery, our leading-edge digital printing machines allow for high speed, premium quality, together with exact volume ordering.

Foiling is a great way to apply metallic designs to your custom washi tapes. Within minutes, you can see a touch of glamour is added to your craft projects with the machine.

An exceptional shimmering effect can take your designs to a new level of creativity with our white ink printing equipment. Be sure to catch the eye with a clean and shining finish.

Ruggedly constructed and precisely designed, our rewinding machine can rewind the exact lengths of rolls to meet your market needs.

With full automatic & electronic precise cutting, it is easy to adjust the tape to a specific width to suit your application.

Quality control of our washi tapes is important for your business success.

Our QC process involves regular patrol inspections during the production process to ensure the printing effect is accurate or if there is any dirt on our washi tapes.

Through our strict standards, all washi tapes allow you to build customer trust.

To make sure each washi tapes are in excellent condition when they reach your room, we perform a full inspection before shipment.

Any defective products are placed in red boxes and discarded. Upon passing all aspects, our tapes get a QC pass stamped before we seal the case.

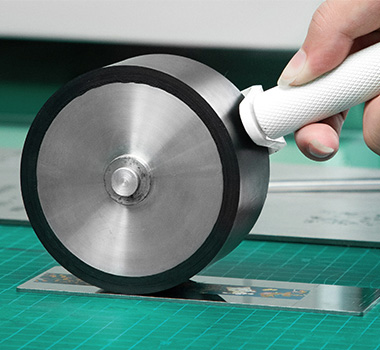

Ensuring all orders have the right appearance, tackiness, and biodegradable factor can help businesses meet any customers’ strict requirements.

The washi tapes have an appealing appearance with no defect.

Adhesive strength of our

washi tapes meet our strict standards.

The foil material or glitter substance should stick to our washi tapes.

All of our washi tapes can be

reused as a sustainable resource.

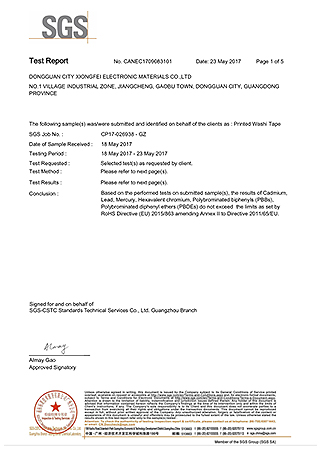

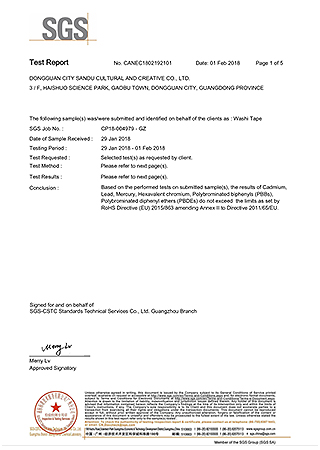

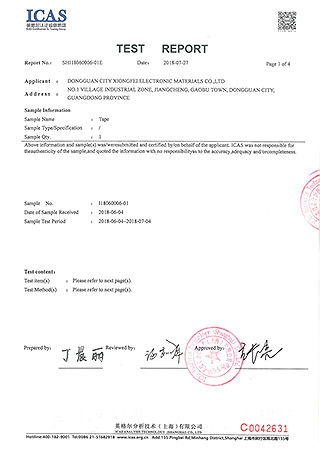

Washi Mill laboratories offer a wide range of tests for washi tape, allowing you to identify any defects and hazards before your product reaches the consumer.

Our patent certificate protects our intellectual property for innovative washi tape that can boost any business market standings.